We provide solutions.

In addition to guaranteeing excellent value for your project, we adapt our proposal to the specific requirements of your installation.

Services

Calculations

Calculations of various kinds are made to choose materials and work to be carried out in the study of a refractory lining. Calculations of heat transfer, volumes, geometries, weights, a combination of bricks for cylindrical or spherical equipment, design of preformed parts, expansion joints, etc.

Definition of materials

The various working conditions of each piece of equipment are studied, such as indoor and outdoor temperatures, combustion gases, gas velocity, production processes, mechanical and chemical stresses for the definition of an optimal coating from all points of view (mechanical, chemical, assembly, maintenance, etc.).

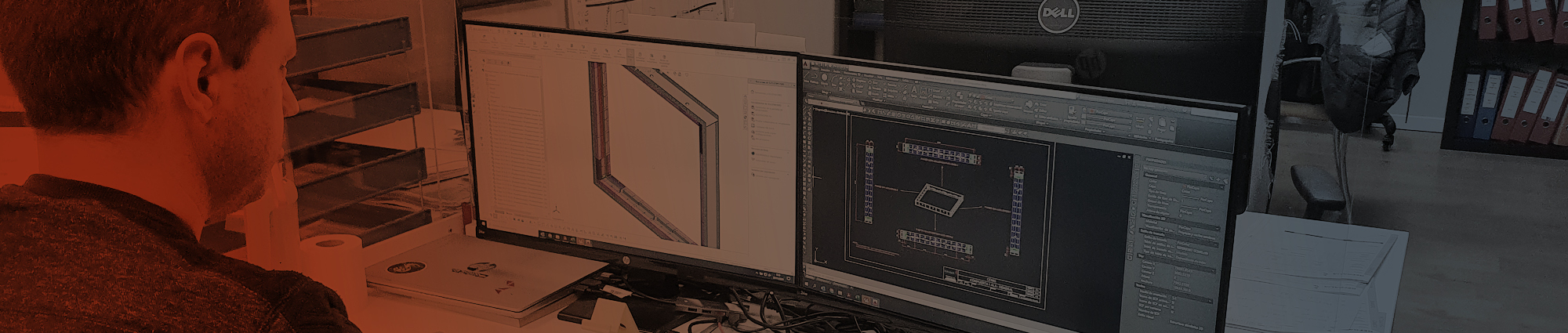

Construction plans

2D and 3D drawings are made both constructive, assembly, anchor welding, and cutting, for the correct definition and execution of the designed works.

Specifications

The materials and thicknesses necessary to comply with the regulations applicable to the various industrial sectors are determined, and the particular requirements of any customer and the installation and commissioning processes thereof.

Technical support

Monitoring the condition and operation of the refractory lining of equipment through thickness measurements, thermography, planning specific or complete repairs, studying improvements in energy efficiency, etc.

Experience, knowledge, equipment

Refralia >> Focused on moving foward >>

> Experience

Our proven experience working in top companies has made us a leading company nationally and internationally.

The team of professionals in our engineering department is the pillar on which the quality assurance of our work rests.

> Human resources

The entire human team works in tune towards a common goal: customer satisfaction from management to the assembly department.

Our team gives us the necessary security and guarantees when tackling the most complex projects.